Vacuum circuit breakers are compact and designed for safe operation, high reliability, and easy maintenance, and are widely used for various types of high-voltage circuits

According to Paschen Curves, high values of dielectric strength of medium can be obtained at very low or very high-pressure levels. The characteristics of insulation at very low-pressure values provide a very low distance between contacts. This distance varies from 10 mm to 20 mm considering the voltage level.

Current Interruption:

Vacuum circuit breakers does not require an interrupting or insulation medium.

The interrupters do not contain ionizable material.

During the separation of current-carrying contacts, contact pressure reduces, real contact surface reduces and the temperature of contacts increases to melting temperature. This produces metal vapors that initiate and support the vacuum arc, maintaining until the next current zero. Due to the special geometry of the spiral contacts, the arc column is kept rotating by the radial magnetic field produced in order to involve a wider surface than that of a fixed contracted arc. Thus, overheating and erosion of the contacts are prevented. So the lifespan of the circuit breaker is increased.

Since there is no interrupting or insulation material in the medium, there are no decomposition gases or particles.

Interruption of High Currents:

• Arcing time is very short (about 6 msec). After the separation of contacts, the current is interrupted in the vicinity of natural current zero.

• The arcing voltage is very low. The short distance between contacts leads to short arc length and the metal vapor provides lower arc resistance. Due to these, arc voltage at the vacuum circuit breaker is about 50-100 V whereas it is about 300 V for SF6 CBs and 500 V for oil circuit breakers.

Electrical Endurance:

The low arc energy provides very high electrical endurance. Besides, the mechanical lifespan of the breaker, instead of how many times the current is chopped, is the characteristic that determines the lifetime of VCB.

The vacuum interrupters used in EVK-type breakers can interrupt “Rated Nominal Current” about 10000 times and can interrupt “Rated Short Circuit Current” 100 times.

Mechanical Endurance:

In regard to the research committed, 75 percent of the circuit breaker faults are caused by the mechanical inadequacy of the breaker. Thus, mechanical endurance is a very important criterion. Vacuum circuit breakers have more advantages than other types of breakers. VCBs involve fewer mechanical components and require less force for open/close operations. This leads to the fact that breakers are subject to less impact, less vibration, and thus, less deformation and corrosion.

Advantages of Vacuum Circuit Breakers:

• Very long lifetime of the contacts (This provides longer breaker life.)

• Less maintenance required

• Less moving parts in a mechanism

• Less force is needed to separate the contacts (since the distance between them is shorter.)

• Environment friendly. Since interruption takes place in a vacuum medium, VCBs do not require gas or liquid addition. This reduces the possibility of leakage of gas (or any material) that can be harmful to the environment.

Operating Mechanism:

• Placed in a metal enclosure having IP20 protection degree.

• Trip-free.

• Suitable for “O-0.3sec - CO-3min - CO” cycle.

The operating mechanism of EVK is a mechanical system based on stored energy within a spring.

» Storing Energy:

• with geared DC motor (electrically)

• with operating handle (manually)

» Releasing Energy:

• with shunt releases (electrically)

• with the open/close button placed on the mechanism (manually)

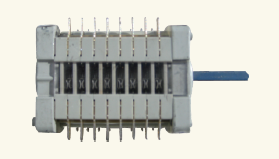

Auxiliary Contact Group:

This contact takes initial force from the drive shaft of the breaker, so changes its position with open/close operations of the breaker. If not specified, the default components are 6 normal open (NO) and normal close (NC) contacts. These are used in the open/close control circuit of the breaker.

Anti-Pumping Device:

The anti-pumping device prevents close operation if electrical commands of open and close appear at the same time. By doing so, the possibility of breaker failure is reduced. The control circuit has an anti-pumping release.

Open/Close Releases:

All mechanisms based on the stored energy principles must have opening and closing releases. The opening/closing releases are used in opening/closing circuits, respectively. The operating voltages of releases must be specified in the order by the client.

Spring Charging Motor:

Used to charge closing spring automatically.

Routine Tests:

• Power Frequency Withstand Test on the main circuit.

• Power Frequency withstand Test on auxiliary and control circuits

• Measurement of the resistance of the main circuit.

• Measurement of opening and closing times.

• Mechanical tests

• Tightness test.