Protection devices for electrical circuits accomplish two main functions namely consistency as well as protection. Protection is assured by detaching the power supply in a circuit through overcurrent protection, removing fire hazards, and electrocution. Additionally, accurate protection may be required to obey organizational principles for some products. Designers must take time to know the different protection devices for circuits. Protection devices are used to protect circuits from extreme voltages or currents. This article discusses what is a protection device, and the types of protection devices used in electrical and electronic circuits.

What is a Protection Device?

A device used to protect equipment, machinery, components, and devices in electrical and electronic circuits against short circuits, over current and earth faults are called protective devices.

Different types of Protection Devices

The different types of circuit protection devices examples include the following.

1.Fuse Wire or Fuse

2.Circuit breaker

3.Earthing or Grounding

1.Fuse Wire or Fuse

2.Circuit breaker

3.Earthing or Grounding

1.Fuse Wire or Fuse

The fuse is the oldest device used to protect electrical circuits and equipment against overload and short circuits.

The fuse can have many forms and shapes depending on its application. Its rating can start from a few mA to several kA.

The fuse link or fuse wire is made of low resistivity material and low melting point.

Type of Fuses:

Depending on the fuse current rating, the fuses can be one of the following types for low voltage applications:

A- Semi-enclosed Fuse (Rewirable)

B- Cartridge Fuse.

C- High Rupturing Capacity (H.R.C) or High Breaking Capacity (H.B.C) Fuses.

A.The Semi-enclosed Fuse:

This type is made from two sections, the base, and the carrier. Both of them are made

from porcelain insulators. The fuse is so designed that the carrier can be safely

withdrawn without danger of touching live parts and the fuse element is so enclosed

that molten metal is safely contained and arcing effectively extinguished.

The simple wire fuse (Fig.1) is connected between two terminals in a porcelain carrier

and is usually threaded through an asbestos tube

|

| Fig.1 |

B.The Cartridge Fuse:

Some of the disadvantages of the Semi - enclosed fuse are overcome if the wire is enclosed in a cartridge-type container. The cartridge may vary in length to match the fuse rating of the circuit to be protected so that the wrong size of fuse cannot be fitted.

The fuse wire does not deteriorate and is more reliable in operation (Fig. 2).

|

| Fig.2 |

C.The High Breaking Capacity (H.B.C) Fuse:

For large currents and where the energy level is high, the high-breaking- capacity (h.b.c.) fuse is used. This is a cartridge-type fuse in which a silver fuse element is connected between two end-contacts of a ceramic tube filled with a special quartz powder. When the fuse blows there is a fusion of the silver vapor produced with the filling powder, so that globules of high-resistance material are formed in the path of the arc, causing it to be extinguished.This type of fuse is very reliable in performance and can be used when discrimination is required. It does not deteriorate and has a high speed of operation (Fig. 3)

|

| Fig.3 |

2.Circuit breaker

A circuit breaker is an automatically-operated electrical switch designed to protect an electrical circuit from damage caused by overload or short circuit. Unlike a fuse, which operates once and then has to be replaced, a circuit breaker can be reset (either manually or automatically) to resume normal operation. Circuit breakers are made in varying sizes, from small devices that protect an individual household appliance up to large switchgear designed to protect high voltage circuits feeding an entire city.

Mainly Circuit breakers operate using one or both of two principles.

They are:

1)Thermal operation relies on the extra heat produced by the high current warming a bimetal strip, which bends to trip the operating contacts.

Mainly Circuit breakers operate using one or both of two principles.

They are:

1)Thermal operation relies on the extra heat produced by the high current warming a bimetal strip, which bends to trip the operating contacts.

2). Magnetic operation is due to the magnetic field set up by a coil carrying the current, which attracts an iron part to trip the breaker when the current becomes large enough.

It must be remembered that the mechanical operation of opening the contacts takes a definite minimum time, typically 20 ms, so there can never be the possibility of truly instantaneous operation. All circuit breakers must have an indication of their current rating.

Types of circuit breaker

There are many different technologies used in circuit breakers and they do not always fall into distinct categories. Types that are common in domestic, commercial and light industrial applications at low voltage (less than 1000 V) include:

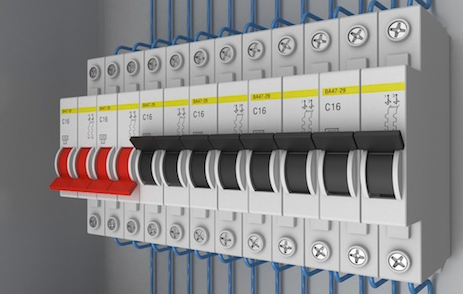

MCB (Miniature Circuit Breaker)—rated current not more than 100 A. Trip characteristics normally not adjustable. Thermal or thermal-magnetic operation. Breakers illustrated above are in this category.

MCCB (Moulded Case Circuit Breaker)—rated current up to 1000 A. Thermal or thermal-magnetic operation. Trip current may be adjustable.

ACB (Air circuit breaker) – rated current up to 4000 A .Thermal and magnetic operation. Trip current adjustable.

Miniature circuit breakers have fixed ratings but moulded case types can be adjusted.

There are many types and ratings of moulded case circuit breakers, and if they are used, reference should be made to supplier's literature for their characteristics. Miniature circuit breakers are manufactured in fixed ratings from 5 A to 100 A for some types, Short circuit ratings for the newer types will be a minimum of 3 kA and may be as high as 25 kA.

The time/current characteristics of all types of circuit breakers are shown.

|

MCB Type |

Range of Operating times (s) |

Current multiple of rating |

|

B |

0.04 to 13 |

x5 |

|

C |

0.04 to 5 |

x10 |

|

D |

0.0.5 to 3 |

X20 |

A comparison of types of protective device

|

Semi-enclosed

fuses |

HBC Fuses |

Miniature

circuit breakers |

|

Very

low initial cost |

Medium initial cost |

High initial cost |

|

Low

replacement cost |

Medium replacement cost |

Zero replacement cost |

|

Low

breaking capacity |

Very high breaking

capacity |

Medium breaking capacity |

3.Earthing or Grounding

Earthing (also known as grounding) refers to contact with the Earth's surface electrons by walking barefoot outside or sitting, working, or sleeping indoors connected to conductive systems, some of them patented, that transfer the energy from the ground into the body.

Earthing of the supply in a house or building serves as a protection for the users. It protects them from electrical shocks when a piece of electric equipment has an insulation failure to ground.